ECOPLEX Film Faced Plywood

Raw Materials: 2+2 or 1+1-layers poplar/pine veneer

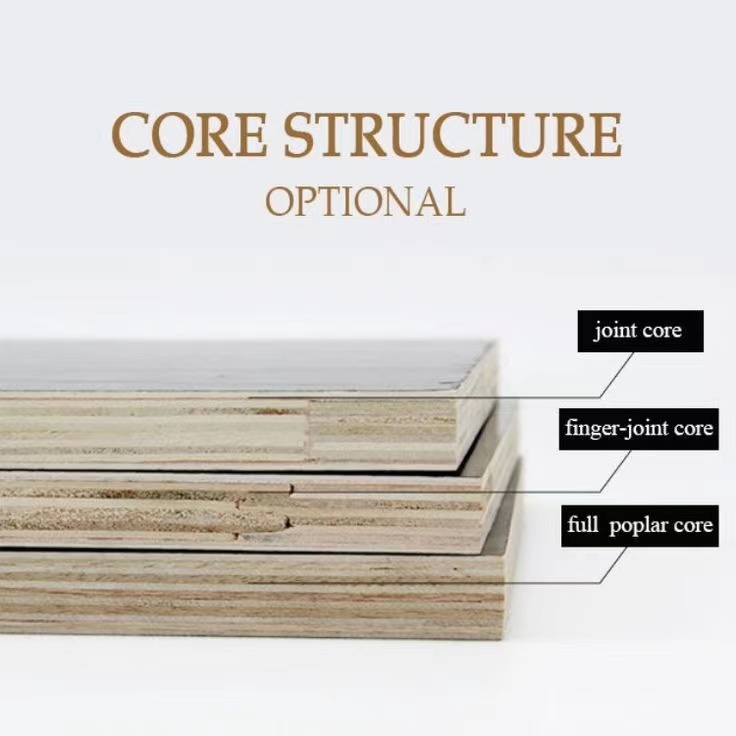

Core: Finger joint core or Joint core (recycled core)

Glue: MR Melamine, Phenolic WBP

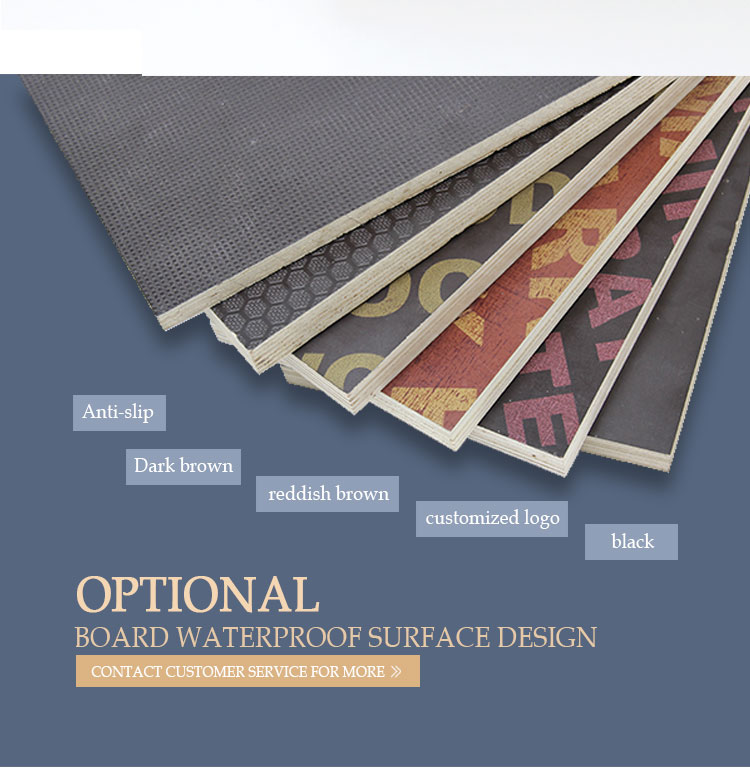

Film: Brown, Black, Red, etc.

Usage times:2-4 times.

Technology:

Recycled film faced plywood uses recycled plywood as the middle core and cover new 2 layers veneers in the top and bottom of recycled middle core, and then be pressed into a new sheet of plywood.

Advantages:

- Recycled film faced plywood is the cheapest product type in global formwork panels.

It can be used 2-4 times under the normal condition.

(note: our customer in South America told us they use Echoplex+ 2 sides for 10 times and when the film is broken they repair and continue using it )

- It saves wood/forest resources by turning used plywood into new plywood.

Use carefully selected 2nd hand plywood to guarantee middle core quality

Pre-treated to clean inner concrete rubbish as best as possible with 90% chance that will not break saw